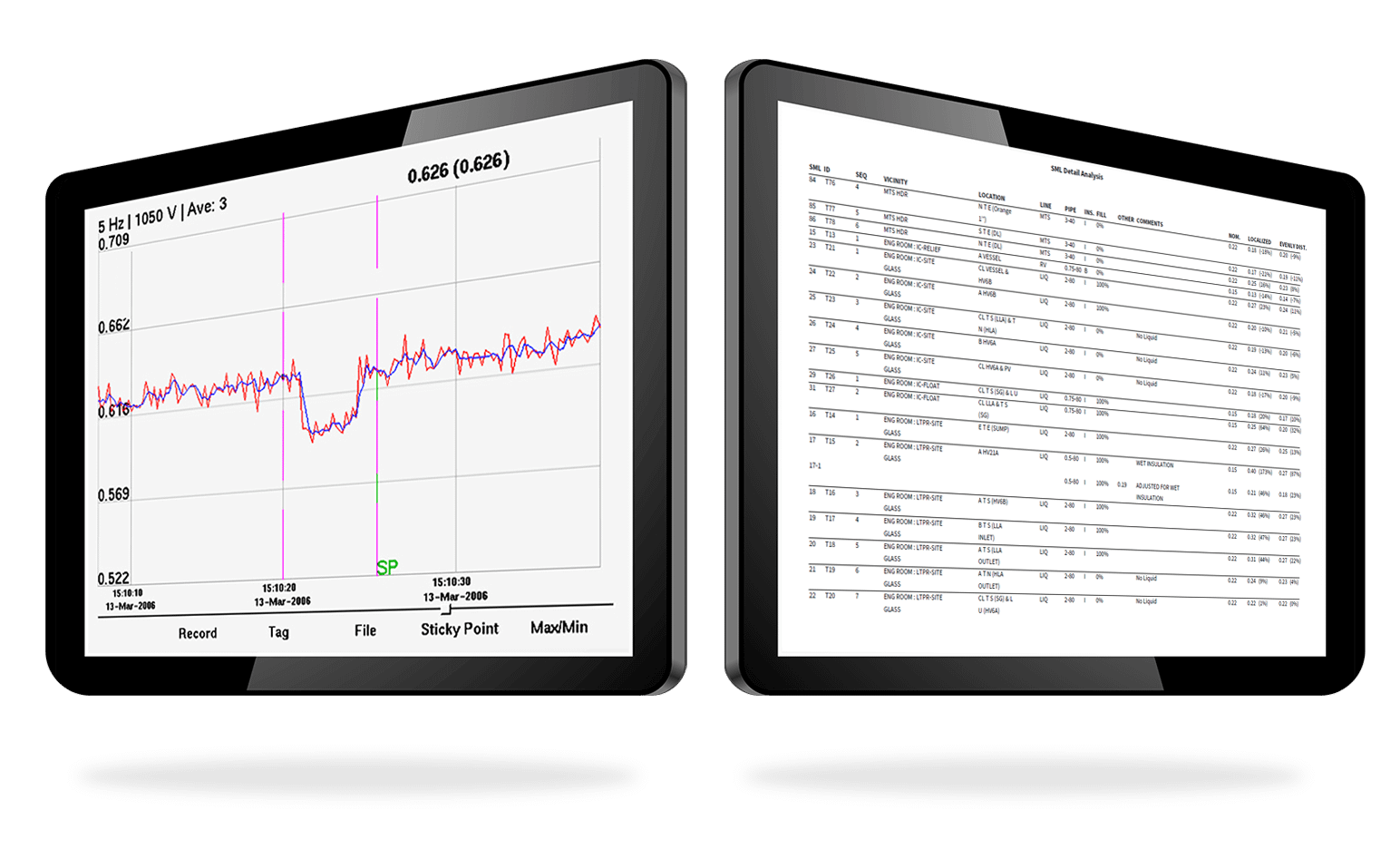

The LIXI Profiler applies Radiometric Profiling (RP), the only NDT technology that detects and measures critical indications of the state of piping without touching a thing.

This fast, real-time non-destructive testing technique measures changes in a beam of gamma-ray energy as it passes through the sample being inspected. The beam source is positioned on one side of the pipe with the detector is on the other side of the pipe, measuring everything in between the source and detector.

The Profiler has proven to be an excellent tool for detecting CUI, High Temperature Sulfidation Corrosion (HTSC), moisture in insulation, liquid levels in piping, and verifying if gate valves are fully open. RP is the preferred NDT method for identifying CUI in the refrigeration industry.